- Easy to use and time efficient - no manual work needed

- Suitable for up to 205 Litre steel and plastic oil drums with 2" BSP fitting

- Suitable for diesel, water, AdBlue, antifreeze, windscreen fluid, mild detergents and agricultural chemicals

- Silenced motor helps to keep the noise at a minimum

- Lightweight design makes it easy to lift in and out of the steel drums

- Easy instructions - ajust length, insert pipe in the drum and tighten, connect to power supply, place nozzle in receiving container, switch the pump on and pull the lever to release liquid

- 16 litres per minute flow rate means the liquid is dispensed rapidly

- Complies to BS EN 13155:2003 standards for non-fixed load lifting attachments

- Comes with E.C Declaration of Conformity (CE certificate)

Make short work of transferring hazardous and non hazardous liquids from a 205 litre steel drum and other drums to another container, this oil barrel and drum electric pump can quickly dispense in bulk. The pump is supplied with a 2" BSP adapter which can be connected to the steel drum. Also supplied with a 230V mains adapter to plug in or 12V battery clips for when there is no access to a mains supply, allowing you to use it wherever.

The pump has a telescopic suction tube that has a stainless steel filter to prevent foreign matter from entering the motor. The tube can be height adjustable to cater to the preference of the operator, making the process as simple as possible.

The drum pump has a flow rate of up to 16 litres per minute, dispensing liquid quickly and efficiently, taking minimal time. Weighing only 2.04kg, the pump itself is extremely lightweight and has a small design, so storing it away in a warehouse or garage will not be a problem. The pump has a section that can house the nozzle to keep it together with the rest of the body.

Instructions

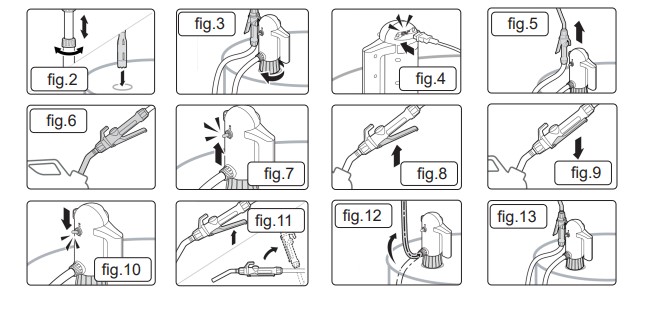

- Adjust the length of the suction pipe to fit the drum (fig.2).

- Insert the suction pipe into the drum (fig.2).

- Tighten the drum bung adapter (fig.3).

- Connect power supply to the pump (fig.4).

- Pull out the nozzle from the nozzle holder (fig.5).

- Place the nozzle into the receiving container (fig.6).

- Switch on the pump by moving the switch up (fig.7).

- Pull the nozzle lever and start supplying the liquid (fig.8).

- Release the leaver when the liquid supply is complete (fig.9).

- Switch off the pump by moving the switch down (fig.10).

- Lift the nozzle up and pull the lever (fig.11).

- Drain the liquid in the hose back into the drum (fig.12).

- Insert nozzle into the nozzle holder for storage (fig.13).